Metal finishing is vital for vehicle durability, especially in commercial and fleet settings. Techniques like dent removal, priming, and high-quality coatings protect against corrosion, rust, and weather damage. Skilled technicians ensure top-quality repairs meeting functional and cosmetic standards, extending vehicle lifespans and reducing maintenance costs.

Metal finishing is an essential process in commercial and fleet vehicle repairs, enhancing aesthetics and durability. This article delves into the various metal finishing techniques tailored for vehicles, offering a comprehensive guide for professionals. We explore best practices specifically for commercial and fleet repairs, emphasizing the critical role of metal finishing in ensuring longevity and protecting against corrosion. By understanding these methods, repair technicians can provide superior services, leveraging metal finishing as a game-changer in vehicle restoration.

- Understanding Metal Finishing Techniques for Vehicles

- Best Practices for Commercial and Fleet Repairs

- Enhancing Durability: The Role of Metal Finishing

Understanding Metal Finishing Techniques for Vehicles

Metal finishing is a critical aspect of vehicle repairs, whether for commercial or fleet purposes. It involves various techniques to enhance the aesthetics and durability of automotive surfaces. One common method is metal finishing through painting, which provides protection against corrosion while offering a sleek, customizable finish. This process demands precision to ensure even coverage and long-lasting results.

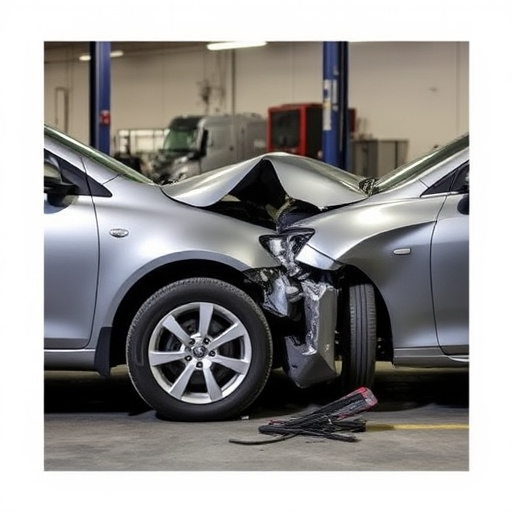

In the realm of vehicle restoration, skilled technicians employ specialized tools for dent removal and precise shaping, followed by meticulous priming and painting. For everyday fleet vehicles, efficient automotive body work techniques are crucial to maintain a professional appearance and protect against environmental damage. Understanding these metal finishing techniques is key to ensuring top-quality repairs that meet both functional and cosmetic standards.

Best Practices for Commercial and Fleet Repairs

When it comes to commercial and fleet vehicle repairs, proper metal finishing is paramount for maintaining durability and aesthetic appeal. Best practices involve utilizing specialized techniques tailored to heavy-duty vehicles. This includes pre-treatment cleaning to remove contaminants, followed by application of high-quality coatings designed to resist harsh environmental conditions.

Automotive repair services for fleets should also prioritize efficient dent removal processes. Quick and effective dent repair not only ensures vehicle readiness but also contributes to the overall efficiency of fleet operations. Regular auto maintenance schedules that incorporate metal finishing and dent removal can significantly extend the lifespan of commercial vehicles, enhancing their value and reducing long-term costs.

Enhancing Durability: The Role of Metal Finishing

Metal finishing plays a pivotal role in enhancing the durability of vehicles, be it for commercial or fleet purposes. This meticulous process goes beyond mere aesthetics; it fortifies the automotive body work against external elements and stresses that vehicles often face during their operational lifecycle. A robust metal finishing treatment creates an impenetrable barrier, protecting the vehicle’s surface from corrosion, rust, and other detrimental effects of weather conditions.

In the event of a fender bender or minor vehicle paint repair, a well-executed metal finishing technique ensures that the repaired area not only blends seamlessly with the rest of the body but also retains its structural integrity. This is particularly crucial for maintaining the overall durability and safety standards of the vehicle. By investing in quality metal finishing, fleet managers and commercial automotive repair shops can extend the lifespan of their vehicles, reducing maintenance costs and keeping their fleets on the road longer.

Metal finishing plays a pivotal role in enhancing the durability, aesthetics, and longevity of commercial and fleet vehicles. By adopting best practices and understanding advanced techniques, repair professionals can significantly improve the overall quality and performance of their repairs. This not only benefits businesses by reducing downtime and maintenance costs but also contributes to safer, more reliable transportation across various industries.